HISTORY OF THE ORGANIZATION

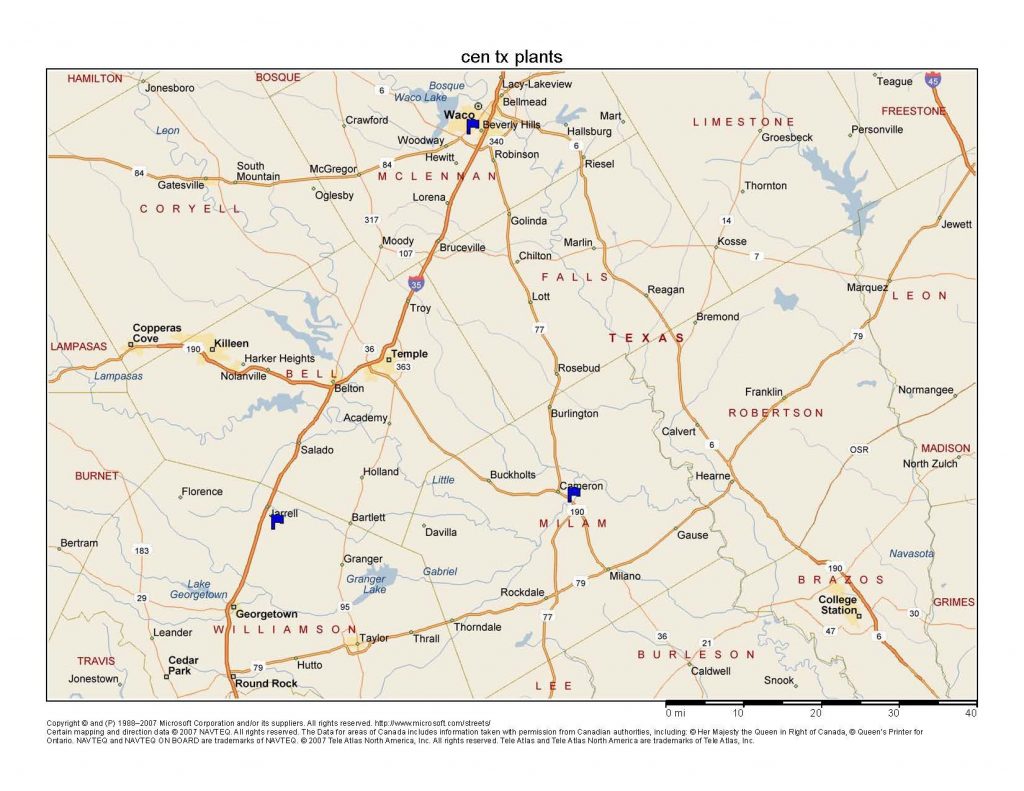

Mine Service employs on average three hundred (300) employees with most of the employees assigned directly to jobs in the field. The home office for Mine Service is located in Rockdale, Texas, with field offices being located on an as needed per project basis. We also have aggregate plant sites in Bronte, Cameron, Hylton and Waco, Texas.

The company’s steady growth and expansion, the satisfaction of our customers, and our reputation all attest to the past history of the company and provide guidelines for our future development.

PHILOSOPHY OF THE ORGANIZATION

Mine Service’s projects cover a diversified work area including the entire state of Texas as well as out-of-state work. Mine Service currently averages annual revenues in excess of forty million ($40,000,000) dollars.

Types of work Performed by Mine Service include the following:

- Building pads

- Subgrade stabilization

- Flexbase installation

- Storm drains

- Curb & gutter

- Asphalt & concrete pavement

- Sidewalks

- Retention ponds

- Brush clearing

- Topsoil/Haulback removal and placement

- Mass overburden removal

- Excavation & transport of lignite, sand or gravel

- Reclamation grading

- Detention pond construction

- Rerouting of waterways

- Revegetation

- Cell excavation

- Groundwater collection systems

- Clay liners

- Geosynthetic liners

- Leachate collection systems

- Protective cover placement

- Cell closures and caps

- Well pads

- Frac ponds

- Roustabouts

- Pressure Washing

- Blasting/Coating/Painting

- Dust suppressant

- Site fencing

- Entrances and access roads

- New plant infrastructure construction

- Ash/Gypsum handling, management, and disposal

- Coal handling and management

- Landfill construction and waste management

- Security fencing installation

- Lakeshore maintenance and repair

- Storm drain/detention pond installation and maintenance

- Concrete paving and structures

- Plant maintenance (street repair, debris hauloff, misc. labor work)

- Millwrights

- Pipefitters

- Boilermakers

- Ironworkers

- Welders

- High voltage systems

- Low voltage systems

- Duct banks

- Conduit runs

- Preparing of right-of-ways

- Excavation and embankment

- Storm drains

- Subgrade stabilization

- Flexbase installation

- Curb & gutter

- Asphalt & concrete pavement

- Topsoil placement

- Driveways

- Road repairs

- Fabriform concrete blanket placement

- Erosion control blanket installations

- Silt fences

- Hay checkdams

- RipRap Rock placement

- Gabions

PERSONNEL

Mine Service maintains a permanent office in Rockdale, Texas where we employ a full time administrative staff. Our heavy equipment operators, as well as our superintendents, average over twenty years plus experience in the heavy construction field.

PLANS FOR GROWTH

Mine Service has enjoyed substantial growth each year since it’s formation and with the management we now have in place, we expect a continued healthy growth.

QUALITY CONTROL

Our method of quality control at Mine Service is to be consistent in performance of our work. We believe quality control begins with the absence of defects in performance and the reduction of variables in our work performance. We achieve this by recruiting and keeping experienced and competent employees.

SAFETY, HEALTH, ENVIRONMENT

Mine Service is sincerely concerned for the safety and health of each employee. Our efforts to provide a safe workplace begin in our job planning process, to ensure we have a full understanding of the job requirements and identify any potential hazards.

We are committed to providing each employee with the training and skills required to perform assigned tasks in a safe manner and to recognize hazards on the job site.

Mine Service is equally committed to protecting the environment on all work sites.

We have implemented a safety program to meet the requirements of OSHA (Occupational Safety and Health Administration) and MSHA (Mine Safety and Health Administration) for our employees.

KEY PERSONNEL

| NAME | POSITION |

|---|---|

| BLAKE DEBAULT | PRESIDENT/OWNER over ten (10) years experience |

| EDDIE NOAK | VP OPERATIONS & ESTIMATING over thirty (30) years experience |

| BRICE TAYLOR | PROJECT MANAGER / ESTIMATOR over thirty (30) years experience |

| ANDREW HOOPER | VP FINANCE over fifteen (15) years experience |

| RYAN REYES | VP BUSINESS DEVELOPMENT fifteen (15) years experience |

| JESS MILLER | VP INDUSTRIAL WELDING fifteen (15) years experience |

| COLT POUNDERS | BUSINESS DEVELOPMENT MANAGER ten (10) years experience |

| JIMMY RAY PEEBLES | CONTROLLER over thirty five (35) years experience |

| ELVIS McQUINN | SAFETY COORDINATOR / AREA SUPERVISOR over thirty (30) years experience |

| DAVID ROEGLIN | AREA SUPERINTENDENT over thirty (30) years experience |

| RAY JARAMILLO | CONCRETE SUPERINTENDENT over thirty (30) years experience |

| ELIAS VALDIVIA | SUPERVISOR over thirty-five (35) years experience |

| JONATHAN MUSTON | SUPERVISOR over twenty-five (25) years experience |

| DAVID HOLDEN | SUPERVISOR over thirty (30) years experience |

| SCOTT MENDOZA | SUPERVISOR over fifteen (15) years experience |

| JIM BLAKELY | SUPERVISOR over fifteen (15) years experience |

| FRANK MORTON | SUPERVISOR over thirty (30) years experience |

| MANUEL LOPEZ | SUPERVISOR over fifteen (15) years experience |

| EDDIE HILL | MAINTENANCE MANAGER over fifteen (15) years experience |

| MATT BELCIK | SAFETY DIRECTOR 25 years experience |

| MIKE REED | SAFETY COORDINATOR 15 years experience |

| RD JOHNSON | TRUCKING & AGGREGATE SUPERINTENDENT 40 years experience |

| BENNY CARRIZALES | SAFETY COORDINATOR 10 years experience |

| SABRINA LEMAY | HUMAN RESOURCES AND PAYROLL MANAGER fifteen (15) years experience |

Mine Service owns and operates an aggregate plant in Central Texas.

The Central Texas plant includes a location in Waco producing washed and crushed aggregate including asphalt aggregate, concrete aggregate, concrete and mason sand, roofing rock, pea gravel, bedding materials, riprap and flexbase.

It is the objective of MINE SERVICE that all projects undertaken are built in accordance with the customers’ schedule, quality requirements and descriptions specified. To insure excellence and consistent work performance on any project undertaken, MINE SERVICE provides a safe and stable working environment for all employees. Safety is the main priority at MINE SERVICE.

To meet and exceed the goals of excellence and profitability, a rigid hands-on safety and maintenance program is provided by MINE SERVICE. Employees are constantly trained and instructed that safety is of the utmost concern and that safety is a personal and individual position that will not be compromised.

MINE SERVICE requires safety training for a new employee before that employee is allowed to begin work at any project location. This is accomplished by the following methods of instruction:

- MINE SERVICE SAFETY REQUIREMENTS

- DRUG TESTING

- SITE SPECIFIC TRAINING

- HAZARD COMMUNICATION (MSDS)

- TASK TRAINING ON ANY AND ALL EQUIPMENT TO BE USED

- JOB SAFETY ANALYSIS (JSA)

- TAG, LOCK & TRY

In addition to the required training listed above, MINE SERVICE mandates that certain site specific training be given to employees before they are allowed to begin work. This training consists of, but is not limited to, the following:

- CONFINED SPACE ENTRY

- NON-QUALIFIED ELECTRICAL TRAINING

- EXCAVATION SAFETY

- ACT OBSERVATION (ALCOA)

- SMELTER ORIENTATION (ALCOA)

- SWITCH YARD ENTRY

- POWER PLANT ORIENTATION (LUMINANT/BECHTEL)

- HAZWOPER (40 HOUR)

- HAZWOPER (8 HOUR SUPERVISOR)

- SCBA (SELF CONTAINED BREATHING APPARATUS)

- TAG, LOCK & TRY (ALCOA)

- COURT YARD ENTRY (ALCOA)

- MSHA TRAINING (MINE SAFETY HEALTH ADMINISTRATION)

Employee training records are checked weekly to insure all training is kept up to date.

In addition to the safety training listed above, safety orientation is given to any employee observed performing an unsafe act.

Safety meetings are conducted weekly for all MINE SERVICE employees or any time a new project is started or a task that has not been performed recently. All meetings are documented and signed by all attending the meeting. Tool box safety meetings are conducted each time an employee is assigned a task.

To insure quality, stability and continuous education for all employees, MINE SERVICE maintains a library of safety manuals and video cassettes. A mutual borrow and loan system is in place with:

- ALUMINUM COMPANY OF AMERICA

- VALLEN SAFETY SUPPLY

- AMERICAN SAFETY ASSOCIATION

- NATIONAL SAFETY COUNCIL

- ASSOCIATED GENERAL CONTRACTORS

- HOLMES SAFETY ASSOCIATION

- NATIONWIDE INSURANCE COMPANY

Employees are provided continuous training both in house and through professional entities such as:

- MINE SAFETY AND HEALTH ADMINISTRATION (MSHA)

- OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION (OSHA)

- TEXAS A&M EXTENSION SERVICE (TEEX)

- THE UNIVERSITY OF TEXAS

- ALUMINUM COMPANY OF AMERICA

- PEC

As indicated by the above training requirements and resources, MINE SERVICE is dedicated to excellence and profitability through constant safety and training of all employees.

To further emphasize, MINE SERVICE’s dedication to safety, all equipment operators are provided EQUIPMENT SAFETY INSPECTION (Pre-Op) forms to be filled out daily. These pre-op inspections are made at start-up of equipment or while making maintenance rounds. Any defects on equipment is reported to the maintenance supervisor.

All equipment is completely inspected and checked by the maintenance superintendent during the week of operation. Appropriate forms are completed, reviewed and filed to develop a history of equipment used by MINE SERVICE.

A daily operation record is also maintained to insure that a 500 hour lubrication and preventative maintenance is completed on a scheduled basis. This is completed by means of a wall chart listing all equipment and by a lubrication decal attached to the specific piece of equipment.